Easy Crush PP zipper

Easy Crush zipper for mono laminates PP (Polypropylene)

The packaging revolution!

Packaging is at the heart of modern industry, and every innovation matters. At Flexico, we have created a PP (polypropylene) zipper that redefines quality and versatility standards in the field of flexible pouches.

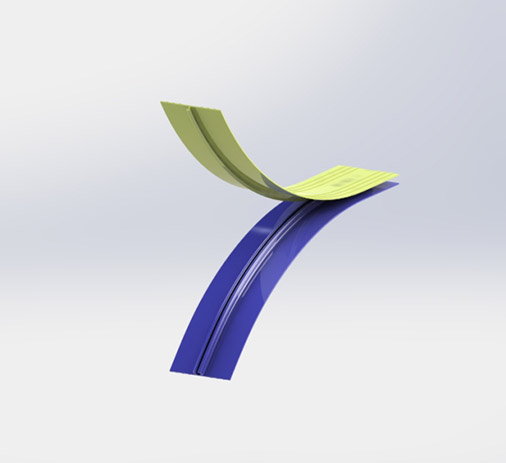

We know that PP is a more rigid material than PE. Developing the perfect PP zipper that adapts to single-material PP films was a challenge that we have met with a particularly well-suited formulation and design. This design allows for welding and crushing without damaging the film while ensuring perfect lateral seal at the zipper level.

Discover how our innovation can improve your packaging processes and satisfy your most demanding customers

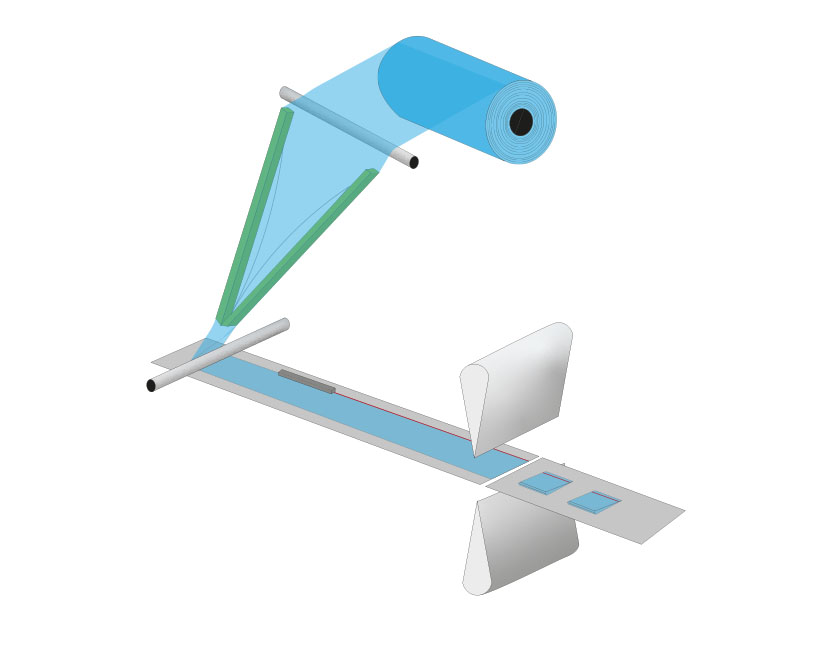

Our Easy crush PP range has been developed to meet the need for eco-responsibility : less material and is designed for mono PP laminates. Our PP zips fit all packaging machines.

Our range of PP zips 100% polypropylene monomaterial is also compatible with PE films (polyethylene).

All our zips are made in France, in our BRCGS-approved production plant, and are suitable for food contact.

Discover the many benefits of our Easy Crush PP (Polypropylene) zipper

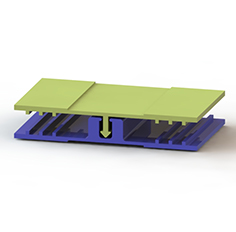

Our Easy Crush zipper is specially designed to ensure better zipper crush and sealing at low temperatures. Better crushing considerably reduces the risk of leaks, offering optimum protection for your products. Low-temperature sealing saves energy and prevents the bag from burning during processing.

When you use our PP zipper, you experience a whole new level of interaction. Our patented Clicky effect zipper provides a distinctive tactile and audible sensation when the pouch is opened and closed. This provides instant feedback on the status of the pouch, guaranteeing an unrivalled user experience.

The PP (polypropylene) range is thinner, which gives it a number of advantages: you can get more length on a reel, and less tax for certain countries.

Our special PP zip is a real technological feat. Designed for mono PP laminates, it is also compatible with PE (polyethylene) layers. This versatility means it can be used extensively in a variety of applications, eliminating the need for different types of sealing layer for different materials.

Weight reduction, carbon reduction :

The lightness of our Polypropylene zip is not just a matter of convenience. It represents a significant step forward in reducing our carbon footprint. By using less plastic, we are directly reducing the CO2 emissions linked to its production. That’s a benefit for you, for the consumer, and above all, for our planet.

Energy savings :

Our cutting-edge technology makes it possible to weld the closure at lower temperatures. This innovative process leads to a significant reduction in energy expenditure during production, making our solution an eco-responsible option.

Optimized production and less waste :

The unique design of our zip closure makes it easy to squeeze over the edge of the bags. This design reduces the risk of leaks and considerably cuts production waste, optimizing the manufacturing process.

PP is renowned for its rigidity, which gives the bag exceptional stability when opened. It also makes it easier to stand upright on the shelf. Good bag stability is essential for brand image.

Our special PP zip is designed to fit all packaging machines. Whatever machine you use in your packaging process, our zip will integrate perfectly, saving you valuable time and resources.

Features :

Easy to crush in the side sealing.

Symmetrical opening force

Zip 200B1/4 – 10.5 mm :

- PP (polypropylene) profile

- 10.5 mm wide

- Sealable on PE & PP film

- Ideal for mono PP laminates

- Compatible with most packaging machines

Zip 202B1/4 – 10.5 mm :

- Tactile and sound effect on opening and closing of the bag (Clicky)

- PP (polypropylene) profile

- 10.5 mm wide

- Sealable on PE & PP film

- Ideal for mono PP laminates

- Compatible with most packaging machines

Available from stock